Our Tradition : We create solutions with quick decisions, flexible manufacturing, and problem solving. With pride, we provide a full range of products and technology from one central shipping point. The needs of our customers will always come first.

PProducts

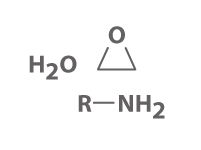

Polyamide Curing Agents

| Polyamide Curing Agents | ||||||||||

| Product Classifications or Composition | Product Code | Note/Commentss | Key Properties | |||||||

| HEW | VISC | Gel Time (min) | ||||||||

| Semi Solid Reactive Polyamide | 8100 | Fast dry primers, Avaiable 100% NV , or Solutions | 525 | na | na | |||||

| 8100 cut 60% IPA and Toluene | 8100IT60 | Fast dry and best corrosion resistance | 525 | X (GH) | na | |||||

| 8100 cut in PM and Xylene | 8100PMX60 | Fast dry and best corrosion resistance | 525 | X (GH) | na | |||||

| 8100 cut in Xylene | 8100X65 | Fast dry and best corrosion resistance | 525 | Y | na | |||||

| Standard high viscosity polyamide | 8115 | Coatings, adhesives | 200 (NV) | 3400(75C) | na | |||||

| Standard high viscosity polyamide in A100 | 8115AR100 | Coatings, primers, higher flash point | 200 (NV) | Z | na | |||||

| Polyamide 115 cut 73% IPA | 8115I73 | Coatings , corrosion resistant primres | 200 (NV) | U (GH) | na | |||||

| Polyamide 115 cut 70% Xylene | 8115X70 | Coatings , corrosion resistant primres | 200 (NV) | W (GH) | na | |||||

| Standard medium viscosity polyamide | 8125 | Coatings , Adhesives, Primers | 105 | 33000 | 120 | |||||

| Standard high imidazole content polyamide | 8140 | Coatings, Adhesives | 100 | 12000 | 140 | |||||

| Low viscosity high imidazoline content polyamide | 8141 | Adhesives , high solids coatings | 100 | 3000 | 160 | |||||

| Low viscosity high imidazoline content polyamide | 8141HI | Adhesives, syntactics, high solids coatings | ||||||||

| Polyamide, lower visc than 8140 | 8142 | General Purpose polyamide | 100 | 8000 | 120 | |||||

| Workhorse modified polyamides for high solids | 8130, 8131, 8145 | Modified Polyamides, viscosity range low to high. Good blush resistance, improved cure and appearance | 135 | 4000 | 50 | |||||

| Low viscosity high imidazoline content polyamide | 8150 | Coatings, adhesives | 95 | 390 | 140 | |||||

| Improved 115 Type, Modified 8115 | 8195X60/XPA 1022 | Improved film properties, excellent adhesion, compatibility and corrosion resistance, better primers and topcoats | 225 (NV) | Y | na | |||||

| Polyamide adduct in Xylene | 8195X65 | Fast dry, good blush and corrosion resistance | 240 | U-Z | na | |||||

| MILspec Polyamide Butanol | 8280B75 | Improved dry, blush and chemical resistance | 170 | 6000 | na | |||||

| MILspec Polyamide PM | 8280PM75 | Improved dry, blush and chemical resistance, HAPS free solvent | 170 | 6000 | na | |||||

| MILspec Polyamide Xylene | 8280X75 | Improved dry, blush and chemical resistance | 170 | 6000 | na | |||||

| Polyamide Adduct in Xylene | 8260X65/8160X65 | Good compatibility and cure, improved dry time and corrosion resistance | 205(NV) | X (GH) | na | |||||

| High Performance Modified Polyamide | 8422 | Expanded working temperature cure response, excellent water and environmental resistance | 114 | 14000 | 60 | |||||

|

Place an order or get more information about Polyamide Curing Agents: |

||||||||||

Amidoamine Curing Agents

| Amidoamine Curing Agents | ||||||||||

| Product Classifications or Composition | Product Code | Note/Commentss | Key Properties | |||||||

| HEW | VISC | Gel Time (min) | ||||||||

| Amidoamine | 8035 | Low viscosity, low blush, high imidazoline, long pot life | 95 | 250 | 400 | |||||

| Medium imidazoline polyamidoamine | 8055 | General purpose, moderate cure. | 95 | 400 | 140 | |||||

| High imidazoline content | 8055-6 | Long working time, improved adhesion and compatibility | 95 | 375 | 240 | |||||

| Low Imidazoline polyamidoamine | 8055-L | Faster cure pure amidoamine | 95 | 400 | 80 | |||||

| Economical polyamidoamine | 8055E | General purpose, lower cost version of 8055, moderate cure rate, medium imidazoline | 95 | 400 | 160 | |||||

| Higher reactivity amidoamine | 8055E-L | Faster cure, pure (unmodified) amidoamine, low imidazoline | 95 | 400 | 90 | |||||

| Accelerated amidoamine | 8073 | DOT non corrosive amidoamine | 67 | 600 | 60 | |||||

| Accelerated / modified Amidoamine | 872 | Shorter working time, improved cure response cold damp | 67 | 800 | 40 | |||||

| Economical accelerated amidoamine | 872E | Short working time with improved cure response, cold damp | 67 | 800 | 40 | |||||

| Modified amidoamine | 8200 | Modified amidoamine, improved cure response, MILSPEC | 93 | 700 | 100 | |||||

| High performance, modified Amido-amine | 8353 | Modified amidoamine, improved blush and cure | 115 | 3000 | 65 | |||||

| High performance, modified Amido-amine | 8396 | Modified amidoamine, improved blush resistance and cure response, higher gloss, low viscosity | 93 | 700 | 100 | |||||

| Modified polyamidoamine adduct | XPA 1037 | Good blush resistance, good cure response | 130 | 300 | 80 | |||||

|

Place an order or get more information about Amidoamine Curing Agents: |

||||||||||

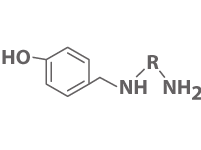

Mannich Curing Agents

| Mannich Curing Agents | ||||||||||

| Product Classifications or Composition | Product Code | Note/Commentss | Key Properties | |||||||

| HEW | VISC | Gel Time (min) | ||||||||

| DETA Mannich Base | 2071 | Rapid cure, cold cure, phenol free | 95 | 750 | 17 | |||||

| IPDA Mannich Base | 2072 | Good cure response, water spot resistant, phenol free | 102 | 200 | 25 | |||||

| DETA Mannich Base | 8208BA80 | Phenol free, high strength grout resin | 47 | 700 | 18 | |||||

| TETA Mannich | 8214 | Fast cure, underwater cure, accelerator | 55 | 5000 | 13 | |||||

| TETA Mannich base | 8214LV | Lower viscosity, fast cure, underwater cure, accelerator | 55 | 2500 | 13 | |||||

| modified Mannich Base, | 8254 | Damp wet bonding, slower cure, low modulus | 152 | 700 | 50 | |||||

| Cycloaliphatic Mannich base | 8309 | Damp wet bonding, cold cure, good bonding wet | 73 | 600 | 30 | |||||

| Cycloaliphatic Mannich base | 8351 | Fast cure, good color gloss, color retention | 76 | 600 | 20 | |||||

| MXDA Mannich Base | 8356 | High modulus fast cure | 73 | 3000 | 13 | |||||

| Cycloaliphatic Mannich base | 81CA | Economy cyclo mannich base | 76 | 125 | 18 | |||||

| Cycloaliphatic Mannich base | 82CA | Good Damp Cure | 101 | 300 | 18 | |||||

| Cycloaliphatic Mannich base | 83CA/8341 | Workhorse cyclo mannich base, low temp cure | 98 | 150 | 20 | |||||

|

Place an order or get more information about Mannich Curing Agents: |

||||||||||

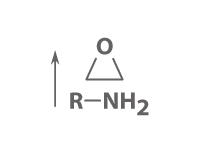

Aliphatic Amine Curing Agents and Accelerators

| Aliphatic Amine Curing Agents and Accelerators | ||||||||||

| Product Classifications or Composition | Product Code | Note/Commentss | Key Properties | |||||||

| HEW | VISC | Gel Time (min) | ||||||||

| Diethylenetriamine | DETA | DETA | 20 | 10 | na | |||||

| Triethylenetetramine | TETA | TETA | 24 | 20 | na | |||||

| Tetraethylenepentamine | TEPA | TEPA | 26 | 70 | na | |||||

| N-AEP Technical grade | AEP | AEP | 43 | 10 | na | |||||

| AEP Substitute | Polyamine 42 | AEP Replacement, lower cost | 43 | 20 | na | |||||

| Economy AEP based amine blend | MK36 | Economy based ethyleneamine blend, replace AEP in some systems | 36 | 80 | 15 | |||||

| Polyetheramine | PPDA | Working offset to D-230 | 60 | 10 | na | |||||

| Polyglycoldiamine | 8022 | Flexible diamine | 55 | 10 | na | |||||

| Low-vicosity modified aliphatic amine | 8089 | Fast Cure, Rapid Development, Low Viscosity , High Modulus, Good Resistance | 72 | 130 | 16 | |||||

| Low Viscosity , modified Aliphatic Amine | 8089LC | Lower Cost Variant of the above | 73 | 150 | 18 | |||||

| Modified aliphatic amine | 8202 | Aliphatic Amine, rapid set, high strength, high chemical resistance | 40 | 4000 | 17 | |||||

| DETA + Phenol (50/50 mix) | 8203 | Deta-Phenol Blend | 41 | 80 | 8 | |||||

| Modified aliphatic amine/ Bisphenol A Adduct | 8205/8238 | Aliphatic Amine, rapid set, high strength, accelerator | 38 | 170 | 13 | |||||

| Modified aliphatic amine/Bisphenol A Adduct | 8205LC | Low cost, higher color, rapid set, high strength accelerator | 38 | 170 | 13 | |||||

| Aliphatic Amine Acceleartor | 8205U | Very fast set, low temp, used as accelerator | 95 | 3000 | 6 | |||||

| TETA Propoxylate | 8206 | Safety Hardener, general purpose aliphatic amine | 48 | 400 | 27 | |||||

| modified amine, 6-8 min gel | 8210 | Fast Set, low viscosity, good toughness, also economical version 8210AF | 96 | 300 | 7 | |||||

| modified Amine, 5-7 min gel | 8211 | Modified amine, 1:1 by volume, also AEP free systems 8211AF, 8210AF | 180 | 6000 | 6 | |||||

| DETA-High MW Epoxy Adduct in solvent | 8213 | Fast Dry, good solvent resistance | 200 | 650 | na | |||||

| Modified amine | 8226 | Low color, high gloss, add toughness | 86 | 300 | 45 | |||||

| Fast cure, aliphatic adduct | 8228 | HMDA adduct, fast , line striping | 85 | 2000 | 11 | |||||

| Dimethylamino Phenol | 8240 | Tertiary Amine Accelerator | na | 20 | na | |||||

| 2,4,6-Tri(dimethylaminomethyl) phenol | 8241 | Tertiary Amine Accelerator, DMP30 type | na | 180-300 | na | |||||

| Modified Amine | 8260HY | High solvent resistance and acid resistance | 48 | 250-400 | 27 | |||||

| Modified Amine | 8267 | Low color, tough, high gloss | 167 | 1200 | 14 | |||||

| Modified aliphatic amine | 8274 | Very low color, modest cure rate, low blush | 85 | 50 | 70 | |||||

| Proprietary aryl aliphatic amine adduct | 8422 | Good Cure Reponse, Benzyl Free , low blush , Good Solvent/Chemical Resistance | 49 | 2000 | 30 | |||||

| Modified aliphatic amine | 8432 | Good Cure response, Good General Performance | 88 | 300 | 25 | |||||

| Accelerated Aliphatic Amines | 8811 | Fastest RT Cure in this class | 95 | 2500 | 5 | |||||

| Accelerator Salt | XPJ 1382 | 40% Active in Ethanol , used to improve film set and dry time | na | 10 | na | |||||

| Accelerator Salt | XPJ 1382SF | Solvent Free version, same benefits as above, not flammable | na | 100 | na | |||||

|

Place an order or get more information about Aliphatic Amine Curing Agents and Accelerators: |

||||||||||

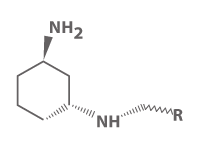

Cycloaliphatic Amine Curing Agents

| Cycloaliphatic Amine Curing Agents | ||||||||||

| Product Classifications or Composition | Product Code | Note/Commentss | Key Properties | |||||||

| (examples, other or custom modified systems are available) | HEW | VISC | Gel Time (min) | |||||||

| Mod PACM Polymer | 8080 | PACM based, good solvent and heat resistance | 115 | 500 | 60 | |||||

| Modified Cycloaliphatic | 8264 | Benzyl Free, PACM based, Good Solvent and Heat Resistance | 57 | 2400 | 110 | |||||

| Modified Cycloaliphatic | 8265 | High solvent and chemical resistance | 95 | 5000 | 24 | |||||

| Modified Cycloaliphatic | 8302 | Good balance of properties, fast thin film set | 114 | 2000 | 22 | |||||

| Modified Cycloaliphatic | 8303 | Benzyl Free , Fast and Low Temp Cure, good aesthetics | 61 | 4500 | 10 | |||||

| Modified cycloaliphatic amine | 8305 | IPDA Free Cycloaliphatic, Good Cure Response | 113 | 400 | 30 | |||||

| Modified Cycloaliphatic | 8323 | Benzyl Free, BPA Free, Fast and Low Temp Cure | 61 | 400 | 10 | |||||

| Cycloaliphatic Amine | 8337 | Low viscosity, excellent cure response, good impact | 75 | 125 | 25 | |||||

| Accelerated Cycloaliphatic Amine | 8339 | Low viscosity accelerated for general purpose | 95 | 150 | 23 | |||||

| Modified PACM Adduct | 8343 | PACM based, low color, good solvent and heat resistance | 115 | 600 | 45 | |||||

| Economy based Cycloapliphatic | 8350/8350C | High thermal and chemical resistance, plasticizer free | 46 | 700 | na | |||||

| Modified Cycloaliphatic (IPDA adduct) | 8355/8382 | Economy based, general purpose | 115 | 1200 | 25 | |||||

| Modified Cycloaliphatic | 8358 | Low viscosity, good balance of properties | 100 | 150-400 | 25 | |||||

| Cycloaliphatic Amine adduct /blend | 8358AH | Modified cycloaliphatic, economy based cyclo | 100 | 250 | 25 | |||||

| Modified Cycloaliphatic | 8361 | Accelerated cycloaliphatic amine, low viscosity, IPDA based | 95 | 55 | 15 | |||||

| Modified Cycloaliphatic | 8364 | General purpose, lowest viscosity IPDA Hardener | 95 | 45 | 28 | |||||

| Modified Cycloaliphatic | 8365 | General purpose IPDA based cyclo for high gloss | 113 | 350 | 30 | |||||

| Modified Cycloaliphatic (IPDA adduct) | 8374 | Low viscosity, improved cure response and blush resistance | 92 | 75 | 25 | |||||

| Modified Cycloaliphatic | 8374V2 | Lower cost version of 8374 | 92 | 125 | 25 | |||||

| Modified Cycloaliphatic | 8381 | General purpose, lowest viscosity IPDA hardener | 95 | 45 | 28 | |||||

| Cycloaliphatic Amine | 8382 | Workhorse cycloapliphatic amine, fast cure response, economical | 115 | 1400 | 27 | |||||

| Cycloaliphatic Amine | 8383 | Low blush, excellent gloss , low yellowing | 95 | 350 | 22 | |||||

| Diaminocyclohexane based amine adduct/blend | 8384 | Good cure response and gloss, also 8384AH economy grade | 88 | 300 | 75 | |||||

| Aliphatic Amine | 8390 | Flexible systems, moderate reactivity | 200 | 1800 | 50 | |||||

| Proprietary aryl aliphatic amine adduct | 8422 | Good cure response, benzyl free, low blush, good solvent and chemical resistance | 49 | 2000 | 40 | |||||

| Modified cycloaliphatic amine, low temp cure | 8289 (also 8489) | Good Early Water Spot Resistance and cure response | 83 | 80 | 28 | |||||

| Diaminocyclohexane based hardener | 8693/8693AH | High chemical resistance | 96 | 150 | 50 | |||||

| Cycloaliphatic Amine Adduct | XPA 1002 | Low emission hardener, improved UV resistance | 95 | 700 | 23 | |||||

| Cycloaliphatic Amine Adduct | XPA 1021 | Low emission hardener, improved UV resistance | 131 | 1400 | 40 | |||||

| Cycloaliphatic Amine Adduct | XPA 1031 | Low viscosity, improved UV resistance | 131 | 95 | 25 | |||||

| Unmodified Cycloaliphatic Amine | IPDA | Improved UV stability, good impact resistance | 44 | 17 | 140 | |||||

| Unmodified Cycloaliphatic Amine | PACM (8388) | Low viscosity, excellent mechanical properties, long pot life | 52.5 | 80 | 210 | |||||

|

Place an order or get more information about Cycloaliphatic Amine Curing Agents: |

||||||||||

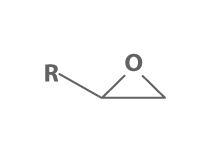

Epoxy Reactive Diluents

| Epoxy Reactive Diluents | ||||||||||

| Product Classifications or Composition | Product Code | Note/Commentss | Key Properties | |||||||

| EEW | VISC | Functionality | ||||||||

| Butyl Glycidyl Ehter (BGE) | RX-1 | Best efficiency, best properties, sensitizer | 145 | 2 | 1 | |||||

| O-Cresyl GE (CGE) | RX-2 | o-CGE, retards crystallization, good maintenance of properties | 185 | 10 | 1 | |||||

| TME TGE | RX-4 | TME TGE, highest reactivity trifuctional | 155 | 250 | 3 | |||||

| p-Tertiary Phenyl GE | RX-5 | lower odor aromatic diluent | 240 | 25 | 1 | |||||

| 2-Ethyl Hexyl GE | RX-6 | efficient, possible replacement for BGE | 225 | 4 | 1 | |||||

| C8/10 GE || C10/12 GE | RX-7 | (Epoxide 7) | 235 | 8 | 1 | |||||

| C12/14 GE (AGE) || C12/16 (E8) | RX-8 | (Epoxide 8) | 290 | 12 | 1 | |||||

| C12- C13 GE | RX-8N | Lower tendency for crystallization with epoxy | 285 | 10 | 1 | |||||

| Isodecyl Alcohol Glycidyl Ether | RX-10 | General purpose, potting, laminating, adhesives | 250 | 12 | 1 | |||||

| dodecanol GE | RX-12 | dodecanol GE | 275 | 7 | 1 | |||||

| DGE of Polypropylene Glycol | RX-32 | PPGDGE, flexible diluent | 320 | 75 | 2 | |||||

| phenol GE | RX-40 | best aromatic diluent for visc reduction | 155 | 5 | 1 | |||||

| 1,4 Butanediol GE | RX-50 | 1,4 BDO DGE, efficient visc reduction difunctional | 130 | 18 | 2 | |||||

| 1,6HDO DGE | RX-51 | safest difunctional diluent | 147 | 20 | 2 | |||||

| Trimethylol Propane TGE | RX-52 | TMP TGE, fast curing, chem resistant, high mechanicals | 150 | 175 | 3 | |||||

| Epoxidized Castor Oil | RX-55 | Castor TGE, flexilizing modifer, renewable ingredients | 600 | 450 | 3 | |||||

| Di-functional Aliphatic Glycidyl Ether | RX-56 | Flexibilizing modifier | 180 | 35 | 2 | |||||

| Cyclohexanedimethanol DGE | RX-57 | difunctional with good mechanical properties | 160 | 70 | 2 | |||||

| Diglycidyl Aniline | RX-60HP | Aromatic difuntional diluent, high Tg, high strength | 110 | 150 | 2 | |||||

| Diglycidyl Aniline | RX-60TG | Higher purity Diglycidyl Aniline | 130 | 220 | 2 | |||||

| Dibromo NPG DGE | RX-63 | FR4 and flame retardant modifier | 260 | 350 | 2 | |||||

| alkyl phenol glycidyl ether | RX-67 | chemical intermediate | 315 | 90 | 1 | |||||

| Neopentylglycol GE (NPGE) | RX-68 | NPG DGE, efficient difunctional lower skin sensitization difunctional | 135 | 18 | 2 | |||||

| Resorcinol DGE | RX-69 | best chemical and solvent resistance, high mechanical properties | 130 | 400 | 2 | |||||

| Neodecanoic Glycidyl ester | RX-70 | Neodecanoic Glycidyl ester | 260 | 10 | 1 | |||||

| Sorbitol Polyglycidyl Ether | RX-80 | Sorbitol Polyglycidyl Ether | 175 | 18000 | 4-6 | |||||

| Sorbitol Polyglycidyl Ether | RX-80LV | Lower viscosity version of RX80 | 185 | 10000 | 4.5 | |||||

| PPG triol TGE | RX-84 | Flexibilizing modifier | 640 | 300 | 3 | |||||

|

Place an order or get more information about Epoxy Reactive Diluents: |

||||||||||

Waterborne Epoxy & Hardeners

| Waterborne Epoxy & Hardeners | ||||||||||

| Product Classifications or Composition | Product Code | Note/Commentss | Key Properties | |||||||

| EEW | VISC | %NV | ||||||||

| BLR -Water 65% | 7128 W65 | BLR -Water 65% | 200 (NV) | 4000 | 65 | |||||

| Water Dispersible BLR | 7128WD | Water Dispersible BLR, with reactive diluent | 200 | 8000 | 100 | |||||

| Water Dispersible BLR | 7128WDHV | Water Dispersible BLR, without reactive diluent | 200 | 17000 | 100 | |||||

| Solid Resin Dispersion | 7301WEP | Solid resin dispersion, EP cosolvent | 500 | 5000 | 55 | |||||

| Solid Resin Dispersion | 7301WPM55 | Solid Resin dispersion, PM cosolvent | 500 | 5000 | 55 | |||||

| Solid Resin Dispersion | 7302W60 | Solid Resin Dispersion, CoSolvent Free | 725 | 5000 | 60 | |||||

| Solid Resin Dispersion | 7305W50 | Solid Resin Dispersion, cosolvent free | 1000 | 5000 | 50 | |||||

| Solid Resin Dispersion | 7309WPM45 | High Molecular Weight (9 type) dispersion, Â EB/EP Cosolvent | 2700 | 2500 | 45 | |||||

| Semi Solid Epoxy Dispersion, | 7334W65 | Cosolvent free, fast dry, improved adhesion, good crosslink density | 250 | 1000 | 65 | |||||

| Semi Solid Resin Dispersion | 7336W65 | Cosolvent free semi solid epoxy resin , faster dry, improved adhesion and flexibility | 300 (NV) | 1000 | 65 | |||||

| WB Polyamine Adduct | 8043W80 | WB Polyamine Adduct, long pot life , DIY | 200 | 15000 | 80 | |||||

| WB Polyamine Adduct | 8048W80 | WB Polyamine Adduct, good cure response, low color | 153 | 7000 | 80 | |||||

| WB polyamide | 8535W50 | WB polyamide | 200 | 8000 | 50 | |||||

| WB Polyamine Adduct | XPA 1042 | Good cure response, low color | 200 | 13000 | 70 | |||||

|

Place an order or get more information about Waterborne Epoxy & Hardeners: |

||||||||||

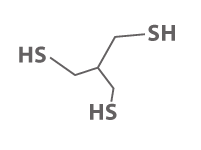

Mercaptans

| Mercaptans | ||||||||||

| Product Classifications or Composition | Product Code | Note/Commentss | Key Properties | |||||||

| HEW | VISC | Gel Time (min) | ||||||||

| Polymercaptan | PM800 | Uncatalyzed Aliphatic polymercaptan | 300 | 14000 | na | |||||

| Polymercaptan | PM800LO | Uncatalyzed, reduced odor | 300 | 12000 | na | |||||

| Polymercaptan | PM800LVE | Lower viscosity than PM800-81 | 290 | 5500 | 3 | |||||

| Polymercaptan | PM800-81 | Precatalyzed Aliphatic polymercaptan, 5 min cure/ gel | 235 | 15000 | 5 | |||||

| Polymercaptan | PM800WR (V2) | Precatalyzed Polymercaptan, improved water resistance & low temperature cure, 5 min cure/ gel | 195 | 3500 | 6 | |||||

| Polymercaptan | PM800-30 | Precatalyzed, longer working time | 300 | 13000 | 30 | |||||

| Polymercaptan | PM80040SEC | Precatalyzed polymercaptan, faster cure, (30-45 seconds), accelerator and adhesiion promoter to glass and steel | 230 | 8000 | 0.7 | |||||

|

Place an order or get more information about Mercaptans: |

||||||||||

Solution Epoxy Resins

| Solution Epoxy Resins | ||||||||||

| Product Classifications or Composition | Product Code | Note/Commentss | Key Properties | |||||||

| (below are examples, other or custom solutions available) | EEW (NV) | VISC | NV | |||||||

| 1 type solution | 7001AR70 | Type 1 solution  Aromatic 100, easy to use, higher flashpoint semisolid epoxy | 500 | Z5 | 70 | |||||

| 1 type solution | 7001AR75 | Higher solids 7001AR70 | 500 | Z6-Z7 | 75 | |||||

| 1 type solution | 7001AREB70 | Type 1 solution cut in A-100 and EB, easy to use, higher flashpoint semisolid epoxy | 500 | Z5 | 70 | |||||

| 1 type solution | 7001CX75 | Type 1 solution MIBK and Xylene | 500 | Z4 | 75 | |||||

| 1 type solution | 7001PM75 | Type 1 solution , propylene glycol methyl ether | 500 | Z5 | 75 | |||||

| 1 type solution | 7001T75 | Type 1 solution toluene | 500 | Z5 | 75 | |||||

| 1 type solution | 7001TBAC70 | Type 1 solution in tBAC, fast dry, medium evaporating solvent | 500 | Z4 | 70 | |||||

| 1 type solution | 7001X75 | Type 1 solution xylene | 500 | Z6 | 75 | |||||

| 4 type solution | 7004KT60 | Type 4 solution MIBK and Toluene | 850 | Z | 60 | |||||

| 7 type solution | 7007CT55 | Type 7 solution in MIBK and Toluene | 1800 | Z2 | 55 | |||||

| 7 type solution | 7007PMA55 | Type 7 solution in Propylene glycol methyl ether Acetate | 1800 | Z4 | 55 | |||||

| 7 type solution | 7007PMT55 | Type 7 cut in PM and Toluene blend, excellent flexibility | 1800 | Z3 | 55 | |||||

| 9 type solution | 7009BD40 | Type 9 cut in EB, excellent flexibility, slow evaporating solvent | 3200 | Z1-Z3 | 40 | |||||

| 9 type solution | 7009DPM40 | Type 9 Cut (also available in PMA, EB, or other solvents) | 2700 | Z1 | 40 | |||||

| High molecular weight Bis F Resin 40% MEK | 7084EK40 | Excellent flexibility, improved hot water resistance | 2800 | X | 40 | |||||

| Semi Solid DGEBPA solution in Butanol | 7134B90 | High solids, improved adhesion and dry time | 250 | Z5 | 90 | |||||

| Semi Solid DGEBPA solution in Xylene | 7134X80 | Lower viscosity version of 7134X90 | 250 | Z3 | 80 | |||||

| Semi Solid DGEBPA solution in Xylene | 7134X90 | High solids, improved adhesion and dry time | 250 | Z6 | 90 | |||||

| Semi Solid DGEBPA solution in Aromatic 100 | 7136A75 | Easy to use, higher flashpoint semisolid epoxy | 300 | Z2 | 75 | |||||

| 4 type Phosphate Ester | 7504EB55 | Improved adhesion and cure , resistance, bake coatings | na | Z4 | 55 | |||||

| 7 type Phosphate Ester | 7507EB50 | Improved adhesion, flexibility and cure | na | Z5 | 50 | |||||

| Modified epoxy solution | 7700CX90 | Hi Solids with Type 1 dry and flexibility, in MIBK and Xylene | 450 | Z3 | 90 | |||||

| Modified epoxy solution | 7707EA65 | Hi Solids 7 Type epoxy for bake cure | 2400 | Z4 | 65 | |||||

| High Solids 7/8 type | 7707EB70 | Low VOC , good flexibility, improve adhesion, slower evaporating solvent | 2400 | Z4 | 70 | |||||

| High Solids modified 7/8 type | 7707EM70 | Low VOC good flexibility and cure | 2400 | Z4 | 70 | |||||

|

Place an order or get more information about Solution Epoxy Resins: |

||||||||||

Voc Exempt Epoxy & Curing Systems

| Voc Exempt Epoxy & Curing Systems | ||||||||||

| Product Classifications or Composition | Product Code | Note/Commentss | Key Properties | |||||||

| EEW or HW (NV) | Visc | NV | ||||||||

| 1 type in Acetone | 7001A80 | Fast dry, low viscosity profile, higher solids | 500 | Z2(GH) | 80 | |||||

| 1 type in DMC | 7001DMC75 | Fast dry, low viscosity profile | 500 | Z2 (GH) | 75 | |||||

| 1 type in exempt solvent blend | 7001OXT70 | Moderate dry time | 500 | Z4 (GH) | 70 | |||||

| 1 type in exempt solvent blend | 7001SP56 | Moderate dry time and evaporation | 500 | Z2 | 56 | |||||

| 1 type in t-BAC | 7001TBAC70 | Fast dry | 500 | Z4 (GH) | 70 | |||||

| 7 type in exempt solvent blend | 7007OXDM50 | Baking enamels, liners, coil coatings | 1800 | Z3 (GH) | 50 | |||||

| semi solid polyamide in exempt solvent blend | 8100OXTA60 | Fast dry, corrosion resistant primers, coatings | 525 | W (GH) | 60 | |||||

| 115 type polyamide in exempt solvent blend | 8115OXT70 | VOC compliant primers, corrosion resistant coatings | 200 | Y (GH) | 70 | |||||

| polyamide adduct in exempt solvent blend | 8280OXT70 | VOC compliant primers, corrosion resistant coatings | 170 | Z4 (GH) | 70 | |||||

|

Place an order or get more information about Voc Exempt Epoxy & Curing Systems: |

||||||||||

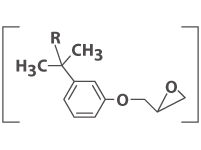

Modified Epoxy and Flexible Systems

| Modified Epoxy and Flexible Systems | ||||||||||

| Product Classifications or Composition | Product Code | Note/Commentss | Key Properties | |||||||

| (examples, other or custom modified systems are available) | EEW (NV) | VISC | NV | |||||||

| LER CGEÂ Cut | 7113 | BLR-CGE | 187 | 600 | 100 | |||||

| LER w/ BGE mod | 7115 | BGE cut, 9% | 175 | 600 | 100 | |||||

| LERÂ RX7 Cut | 7117 | BLR-E7 | 190 | 600 | 100 | |||||

| C12/14 alcohol GE | 7118 | BLR-E8 | 194 | 600 | 100 | |||||

| C12/C14 alcohol GE | 7119 | BLR-E8 | 190 | 1800 | 100 | |||||

| C12/C14 alcohol GE | 7119HV | BLR-E8 | 188 | 6500 | 100 | |||||

| Blend of 7128 and 7430 | 7120 | Medium viscosity, good pigment wetting, reduced tendency to crystallize | 190 | 5500 | 100 | |||||

| LER cut with COGE | 7121 | Flexibilized with COGE | 260 | 1400 | 100 | |||||

| BPADGE - high purity | 7125 | Electronics, Composites, Castings | 174 | 3000 | 100 | |||||

| BPADGE - low vis, low reactivity | 7126 | BPADGE, lower reactivity, lower viscosity | 182 | 9500 | 100 | |||||

| LER-RX 5 3.5% | 7127 | Easier handling, better crystallization resistance than standard LER | 190 | 8000 | 100 | |||||

| Standard DGEBPA resin | 7128 | BLR-BPADGE | 186 | 13000 | 100 | |||||

| Standard DGEBPA resin cut in Dibutyl Phthalate | 7128DBP | Toughened epoxy with low viscosity | 310 | 300 | 100 | |||||

| Higher visc/reactivity BPADGE | 7129/7130 | Higher visc BPADGE | 192 | 21000 | 100 | |||||

| Higher viscosity DGEBPA resin (LER) | 7134 | Semi-Solid LER, Â neat | 235 | na | 100 | |||||

| Semi Solid DGEBOA epoxy, cut in BGE | 7134BGE | Solven free-semi solid epoxy cut | 235 | 20000 | na | |||||

| High viscosity DGEBPA resin | 7136 | Good film former, improved film cure, improved flexibility over standard resin | 325 | semi solid | 100 | |||||

| BLR / Acrylate monomer | 7137 | BLR-TMPTA | 155 | 1050 | 100 | |||||

| LER - HDDA@40% | 7138 | Very low visocosity fast cure, flexibility and gloss | 170 | 120 | 100 | |||||

| LER- HDDA @20% | 7138HV | Easier to handle improved cure and gloss | 170 | 6000 | 100 | |||||

| Bisphenol A DGE Resin | 7139 | Improved cure response, cures down to 35F, modest viscosity | 315 | 3500 | 100 | |||||

| Bis A / Bis F, AGE | 7153 | Low viscosity, crystallization resistant good properties | 185 | 1000 | 100 | |||||

| LER -modifified with polyglycol diglycidyl ethers | 7155 | Moderate Viscosity and Reactivity, improves impact and chip resistance | 280 | 1500 | 100 | |||||

| LER - HDDA @10% | 7161 | BLR-10% HDDA | 175 | 2000 | 100 | |||||

| Aliphatic Epoxy | 7180 | HBPADGE (Hydrogenated) | 235 | 3000 | 100 | |||||

| LER-Sorbitol PGE cut | 7181 | HBPADGE -Sorbitol GE cut | 225 | 5000 | 100 | |||||

| Elastomer Modified Difunctional Diluent | 7208 | 2 phase systems, improved adhesion, thermal shock and toughness | 300 | 6000 | 100 | |||||

| 40% Elastomer Modified LER | 7213 | 2 phase systems, same as 7213LV, but higher tensile and modulus | 325 | 650000 | 100 | |||||

| 40% Elastomer Modified LER | 7213LV | 2 phase systems, high impact, improved adhesion, elongation | 325 | 225000 | 100 | |||||

| Novolac modified butadiene - acrylonitrile | 7241 | 2 phase systems, toughening, higher viscosity, high elastomer, improved peel strength | 315 | 250000 | 100 | |||||

| Elastomer modified Difunctional Diluent | 7242 | 2 phase systems, improved adhesion, good compatibility | 350 | 22500 | 100 | |||||

| Thermoplastic Rubber Modified Epoxy | 7243 (1443M) | Improved adhesion to vinyl and olefin substrates | 230 | 35000 | 100 | |||||

| Elastomer modified LER | 7246HV | Good thermal shock, improved adhesion to vinyl | 250 | 35000 | 100 | |||||

| Flexibilized Epoxy | 7258 | Flexible liquid epoxy blend | 460 | 6000 | 100 | |||||

| Flexibilized Epoxy | 7264 | BLR, Urethane, Â HDDA | 220 | 2500 | 100 | |||||

| BLR-Urethane modified | 7265 | Urethane modified epoxy , good cure response and flexibility | 235 | 5000 | 100 | |||||

| Dimer Glycidyl Ester | 7271 | Flexibilizing modifier | 425 | 700 | 100 | |||||

| Dimer mod epoxy | 7272 | Dimer mod epoxy | 675 | 3000(75% NV) | 100 | |||||

| CTBN Modified BPADGE | 7295 | 2 phase systems, toughening, 5% elastomer | 210 | 30000 | 100 | |||||

| Aliphatic epoxy | 7800 | HBPADGE (Hydrogenated) | 235 | 3000 | 100 | |||||

|

Place an order or get more information about Modified Epoxy and Flexible Systems: |

||||||||||

Bisphenol F & Novolacs

| Bisphenol F & Novolacs | ||||||||||

| Product Classifications or Composition | Product Code | Note/Commentss | Key Properties | |||||||

| (examples, other or custom modified systems are available) | EEW (NV) | VISC | NV | |||||||

| BISHENOL Â F RESIN | ||||||||||

| BIS F | 7430 | BPFDGE | 165 | 4000 | 100 | |||||

| PHENOL NOVOLAC EPOXY | ||||||||||

| Novolac | 7431 | 2.6 functional | 168 | 1200 (52C) | 100 | |||||

| Novolac | 7432 | 2.3 functional | 170 | 22000 | 100 | |||||

| Novolac | 7434 | 2.2 functional | 170 | 8000 | 100 | |||||

| Novolac | 7435 | 2.5 functional | 173 | 55000 | 100 | |||||

| Novolac | 7438 | 3.6 functional | 174 | 30000 (52C) | 100 | |||||

| Modified Novolac | 7469 | 3.6 Novolac cut w/ RDGE | 160 | 5000 | 100 | |||||

|

Place an order or get more information about Bisphenol F & Novolacs: |

||||||||||

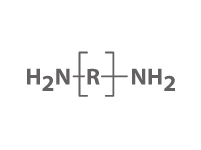

Amino Resins for Polyurea

| Amino Resins for Polyurea | ||||||||||

| Product Classifications or Composition | Product Code | Note/Commentss | Key Properties | |||||||

| (examples, other or custom modified systems are available) | HEW | VISC | Gel Time (min) | |||||||

| Hindered Amine (proprietary) | 87 | Similar to 158, but softer segment | 290 | 110 | 6 | |||||

| Hindered Amine (proprietary) | 138 | Long pot life, inherently tough, highest elongation | 315 | 340 | 27 | |||||

| Hindered Amine (proprietary) | 140 | Moderate reactivity, inherently tough, higher elongation | 315 | 340 | 27 | |||||

| Hindered Amine (proprietary) | 140S | Longer Pot Life version of 140 | 340 | 300 | 35 | |||||

| Hindered Amine (proprietary) | 144 | Hybrid hindered amine, excellent balance of hardness, chemical resistance, working time, inherently tough | 250 | 400 | 35 | |||||

| Hindered Amine (proprietary) | 145 | Hybrid Hindered Amine excellent balance of hardness, chemical resistance, working time, inherently tough | 320 | 900 | 35 | |||||

| Hindered Amine (proprietary) | 146 | Hybrid hindered amine, excellent balance of hardness, chemical resistance, working time, inherently tough | 235 | 250 | 45 | |||||

| Hindered Amine (proprietary), in PMA | 147 | 85% NV in PMA, maximum working time, low viscosity | 275 | 90 | 80 | |||||

| Hindered Amine (proprietary) | 158 | High Reactivity, hard segment for plural systems | 235 | 200 | 5 | |||||

| Hindered Aliphatic Amine, linear | 220 | High Reactivity, hard films, accelerator or spray | 233 | 80 | 5 | |||||

| Hindered Cycloaliphatic Amine | 420 | Moderate reactivity, hard films | 275 | 900 | 20 | |||||

| Hindered Amine (cycloaliphatic) | 520 | Slow reactivity, Hard Films, often blended with 420, 140, and 145 to increase working time | 290 | 1600 | 100 | |||||

|

Place an order or get more information about Amino Resins for Polyurea: |

||||||||||

Oxazolidines & Aldimines

| Oxazolidines & Aldimines | ||||||||||

| Product Classifications or Composition | Product Code | Note/Commentss | Key Properties | |||||||

| (examples, other or custom modified systems are available) | HEW | VISC | ||||||||

| OXAZOLIDINES | ||||||||||

| 2 ethyl hexyl based oxazolidine | Arnox 2 | Highly efficient moisture scavanger | 227 | 50 | ||||||

| 1,3 Oxazolidine (hydroxy ethyl Oxazolidine) | Arnox 3 | Building block for modified 1,3 Oxazolidines, scavenger | 159 | 50 | ||||||

| Urethane Oxazolidine | Arnox 4 | Urethane bis Oxozolidine, 4 functional, single pack and 2K | 122/244 | 6000 | ||||||

| Modified Oxazolidine | Arnox 4/LV50 | Blend of LV and Arnox 4, providing low viscosity and higher freezing point | 104/207 | 500 | ||||||

| Modified Oxazolidine | Arnox NC | Blend of LV and Arnox 4, providing higher freezing point | 100/200 | 3000 | ||||||

| Carbonate backbone Oxazolidine | Arnox LV | Â Low viscosity, 4 functional. Â Excellent UV resistance | 90/180 | 50 | ||||||

| Bis Oxazolidine | XPA 1054 | Urethane bis oxazolidine, 4 functional, single pack and 2k with lower odor | 150/300 | 7000 | ||||||

| ALDIMINES | ||||||||||

| Aldimine Reactive Diluent | Arnox 6 | Reactive diluent and pot life retarder for 2k systems, improves thin film set, diluent for 1K | 139 | 25 | ||||||

|

Place an order or get more information about Oxazolidines & Aldimines: |

||||||||||

AAbout

Based in Richmond, Missouri, our company has a tradition of providing a full range of products and technology to the thermoset polymer industry. Fast decisions, flexible manufacturing, Custom and Toll Manufacturing, and problem solving is our core business model.

Our product line is one of the most comprehensive offerings of epoxy and polyurethane intermediates produced in North America. All available from the same centralized U.S. shipping point.

“We form strong bonds with our customers”

GGallery

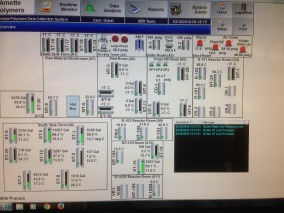

Our 21 acre facility consists of 80,000 square feet of manufacturing and warehouse space. Manufacturing equipment includes chemical reactors ranging in size from 9,000 gallons to 175 gallon pilot units. In addition, blending vessels range in size from 10,500 gallons to 1,000 gallons. This is all supported by a state-of-the-art process control laboratory. Our most valuable asset is our talented and dedicated staff. Weighing in at just over 5,000 lbs, our staff is more than just a few tons of pride, service and knowledge. (bottom right)

CContact Us

View Arnette Polymers, LLC in a larger map

Arnette Polymers, LLC

8905 Wollard Blvd.

Richmond, MO 64085

CALL:

816-776-3005

FAX:

816-776-2488

PPrivacy Policy

Please click here to read our privacy policy.